FABARM company - Presentation and ranges of rifles

Founded around 1900 and descended from a great Brescian dynasty, the Galesi family. Fabarm comes from FABBRICA BRESCIANA DI ARMI which means “Arms Factory of Brescia”.

During the first decades of the 20th century, production consisted solely of side-by-side rifles and pistols. It was after the end of the Second World War that superimposed rifles appeared. Then in the mid-1950s, Fabarm launched the production of air rifles and weapons in Cal. 9mm Flaubert.

At the end of the 1960s, the first semi-automatic rifle, the “GOLDENMATIC”, appeared.

The 1970s confirmed the industrial dimension of Fabarm with an expansion of the range: superimposed competition rifles (STL model); juxtaposed rifles with 4 hooks; pump-action shotguns and the semi-automatic ELLEGI gas-fired shotgun.

Fabarm has perfectly managed and anticipated the shift of the 2000s by investing massively in human resources, placing research and development at the center of its product policy. It is one of the first companies in the sector to acquire machining centers and robots and organizes its production on a just-in-time basis.

The new millennium corresponds to a 3rd wind, Fabarm files important patents for the future of the brand (TRIBORE barrel; PULSE piston; HP chokes; AXIS rifle etc.). It is also the recognition of modern design recognized as modern, taut and innovative which creates a real Fabarm identity.

The company's commercial activity is carried out in partnership with more than 700 gunsmiths throughout the country, including around a hundred FABARM EXPERT points . The location of our premises is ideal geographically and allows us to ensure delivery within 24 hours throughout France.

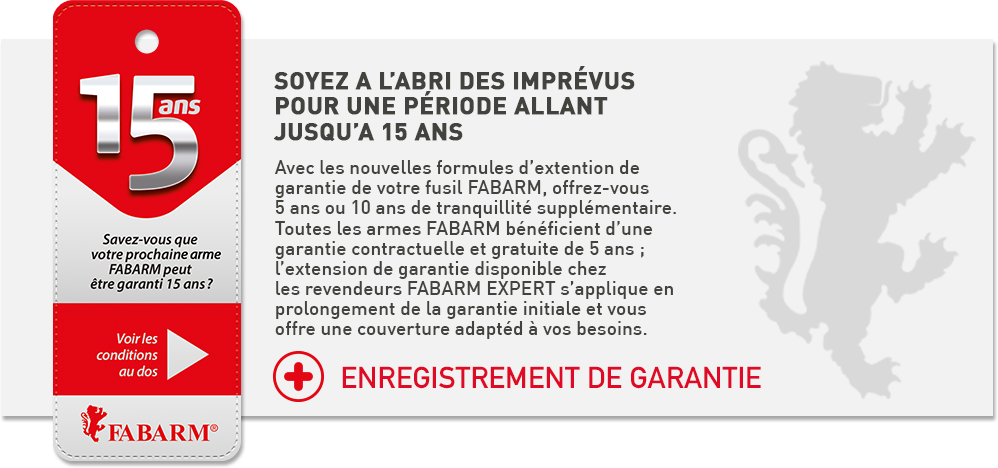

Fabarm warranty extension

In 2013, FABARM decided to support you over the long term by offering you an exceptional guarantee that can last up to 15 years!

Click on the image to see an example of the Fabarm warranty extension:

Three guarantee options are available to you:

- Free contractual warranty lasting 5 years

- Guarantee up to 10 years for an amount of €100

- Guarantee up to 15 years for an amount of €150

The warranty extension is available across the entire FABARM range, including sports weapons. It covers the same points as the contractual guarantee granted by FABARM to new weapons.

Find all the conditions and advantages by clicking on this link or by asking your gunsmith!

Different ranges of products are available to you

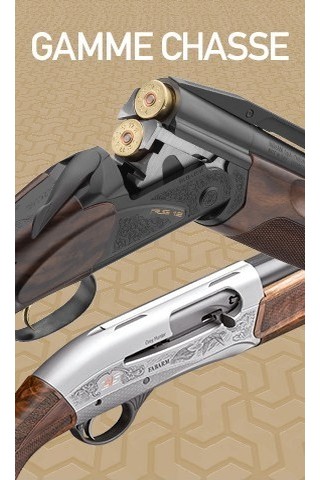

Hunting range:

The ELOS range, proven at 1630 BAR, offers an Ergal 55 action frame, an oiled walnut stock, and a lightweight Tribore HP barrel.

The SDASS 2 hunting range takes advantage of the excellent fluidity of the pump mechanism with its symmetrical control arm with double rods. The Ergal 55 carcass provides perfect balance.

>ELOS A2 Classic Field Gold Cal. 12

>ELOS A2 Classic Field Gold Cal. 20

> ELOS A2 Classic AL Gold Cal. 12

> ELOS A2 Classic AL Gold Cal. 20

> Slug ELOS Al Traqueur Classic Gold Cal. 12

> ELOS A2 Classic Paradox Al Gold Cal. 12

> Superimposed rifle ELOS A2 Notte Field Cal. 12 steel

> Superimposed rifle ELOS A2 AI Notte Cal. 12 Ergal

> ELOS 2 Elite Cal superimposed rifle. 12 or Cal. 20

> SDASS 2 Large Game Cal.12 pump shotgun

> SDASS 2 Composite Hunting Pump Shotgun Cal. 12

> SDASS Pro Telescopic Stage 2 Cal. 12

> SDASS Pro Forces Stage 2 Cal. 12

> SDASS 2 Hunting Gray Cal. 12

> SDASS 2 Hunting Waterfowl Max 5 Cal. 12

> Semi-automatic XLR AB Cal. 12

Rifled weapons:

The Asper 2 line is an innovative express with a steel rocker, with adjustable convergence.

Their rounded action makes the rifle elegant and fluid.

> Express rifle ASPER 2 Classic Gold Light Cal. 8x57 JRS

> Express rifle ASPER 2 Classic Gold left-handed Cal. 30BR

> Express rifle ASPER 2 Classic Gold Cal. 30BR; 8x57 JRS; 30-06 Spr; 9.3x74R

Competition range:

The ELOS N2 line thinks outside the box with innovative style. The matte black finish highlights the modern and minimalist engraving. Weapons tested at 1630 BAR. The lightweight Tribore HP cannon has a 6mm sight band.

The AXIS S&H range has a lightweight barrel and a stock designed for range hunting but also for waterfowl hunting. Its weight allows for perfect balance, but also makes it lively, fast and stable.

> ELOS N2 FIXED TRAP superimposed rifle Cal. 12

> ELOS N2 TRAP AS superimposed rifle Cal. 12

> AXIS Sport & Hunting S&H Cal. 12

Shotgun :

Martial shotguns have a rifled barrel. The so-called "PRO FORCES" stock allows you to hold the weapon even with one hand.

The STF/12 shotguns are based on a fully modular rifle whose central platform allows modification of the length of the weapon, stock, etc. It combines performance, fluidity and quality.

> MARTIAL KARBON pump action shotgun Cal. 12

> MARTIAL FR pump shotgun Cal. 12

> MARTIAL CANTILEVER pump action shotgun Cal. 12

> MARTIAL OD GREEN pump action shotgun Cal. 12

> MARTIAL ULTRASHORT pump shotgun Cal. 12

> MARTIAL Cerakote blue shotgun Cal. 12

> Professional pump shotgun STF12 Compact black Cal. 12

> Professional STF12 Pistolgrip Viper Green Cal. 12

> Professional STF12 Pistolgrip OD Cal. 12

> Professional STF12 Pistolgrip Tactical Cal. 12

> STF 12 SHORT BLACK pump shotgun Cal. 12

Accessories :

You will find a wide range of clothing and accessories for your weapons or equip yourself with shooting vests, caps etc.

> Spare parts: Barrels, chokes

> Spare parts: Barrel collars, recoil reducers

> Picatinny type rail mounting

> Hit All Terrain for Fabarm XLR 5

> Caps

> Luggage: Scabbards, cartridge bags, covers

> Side support 4 or 5 cartridges

> Mil-Std 1913 21mm Picatinny Rail

> Straps

Exclusive Fabarm features

1. Tribore HP BARREL barrels

STEEL BALLS: A LENGTH AHEAD FOR FABARM!

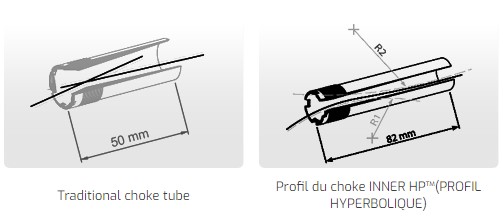

Exclusive: Fire steel ball cartridges in Fabarm INNER HP™ & EXIS HP™ chokes larger than half-choke.

All weapons manufacturers, today like Fabarm, allow the firing of steel shot cartridges only in interchangeable chokes whose constriction does not exceed half-choke. This is due to the recommendations of the CIP which establishes as a maximum limit an angle of 1 degree inside the chokes.

On this sketch the choke with a length of 50 mm (certain 65 mm chokes have the same geometry) is composed of a conical part (40 mm) and a cylindrical or slightly open part of 10 mm in order to allow for projectiles to stabilize before the muzzle of the gun. The half-choke limit for firing steel shot is thus the consequence of the fact that a cone 40 mm long with a cone of 0.5 mm corresponds to a cone with an angle of approximately 1 degree.

Consequence : No manufacturer gives you the possibility of firing steel cartridges in ¾ and full chokes.

Fabarm is therefore today with the INNER INNER HP™ and EXIS HP™ chokes, the only manufacturer to allow “high performance” steel cartridges to be fired in chokes superior to the half-choke (and this while of course respecting the standards of the CIP).

How?

1- By increasing the length of our chokes:

• INNER HP™ CALIBER 12: 82 mm

• INNER HP™ CALIBER 20: 82 mm

• EXIS HP™ CALIBER 12: 92 mm

2- By replacing the usual rectilinear cone with 2 curves thus avoiding the presence of a sharp angle in the choke (better progressivity, less friction)

These HYPERBOLIC™ chokes have been patented by FABARM.

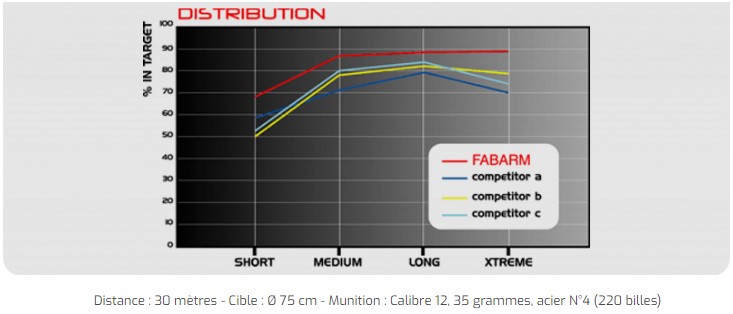

Here are the shooting results:

ANALYSIS:

HAS

Being able to use chokes that are more closed than the half-choke is an essential advantage for the hunter. So when competing guns have an average efficiency of 76% with its ½ choke, firing the same cartridge with the FABARM INNER HP XTREME choke (0.9) allows an efficiency of 89%.

These are concretely 40 more impacts within the 75 cm target! = 15% impact

B

This result does not only come from the INNER HP choke but also from the profile of the TRIBORE barrel (PATENTED).

The TRIBORE barrel is the only barrel that does not have the disadvantages of overbored barrels already on the market, namely a loss of penetration.

A little history :

The overbored barrel seeks to improve the sheaves by essentially seeking to reduce friction and therefore the number of damaged balls which do not have a straight trajectory.

It was born for sporting disciplines (sporting and trap), penetration not being essential when it is simply a question of breaking a clay plateau.

First consequence of this type of gun: If we compress the same quantity of combustion gas from a cartridge in a larger space (the gun having a diameter of 18.85 mm instead of 18.40 mm), the pressure is lower. So the penetration, the famous kinetic energy (Ec= ½ mv2) decreases. And don't think that the speed increases simply because of a reduction in friction!

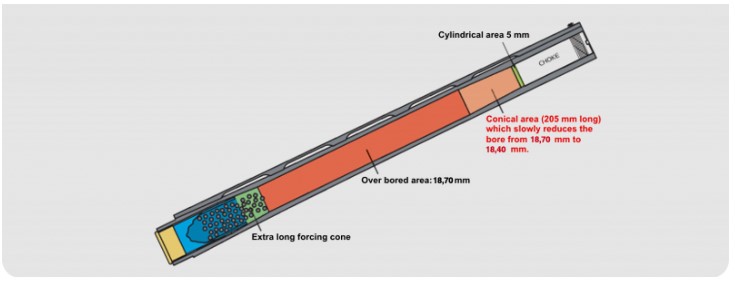

So the TRIBORE cannon?

This gun, developed approximately 10 years after the back-bored guns, is the practical application of Mr. Venturi's principle which says that if we reduce the diameter of a tube, the speed of the fluid inside this tube increases. systematically.

We have proof of this by washing our car with a water hose. We pinch it, the pressure increases! Well it’s the same with our TRIBORE cannon.

The TRIBORE barrel in 2 words:

• An overbored part to reduce friction and recoil.

• A reduction in the diameter of the tube to increase the speed of the balls (Venturi principle).

VS

The drilling production process of FABARM cannons:

All our competitors produce their rifle tubes by cold hammering, for reasons of production costs. This process, which is excellent for rifled barrels, is not so for smoothbore weapons. The steel thus obtained is too rigid, not very elastic and above all all the tensions created during hammering will be restored during passage in the oven (a little over 700 ° C) for the welding of the strips and tubes.

The cryogenics put forward by certain competitors only aim to limit the deformation of the barrels during the welding phase by freezing the internal tensions of the steel a little.

But there is a much more valid solution for producing excellent quality tubes: drilling chrome molybdenum steel bars.

It is this technology that Fabarm uses for all tubes when our 2 major competitors are limited to using this technology only for their CUSTOM SHOP and luxury weapons.

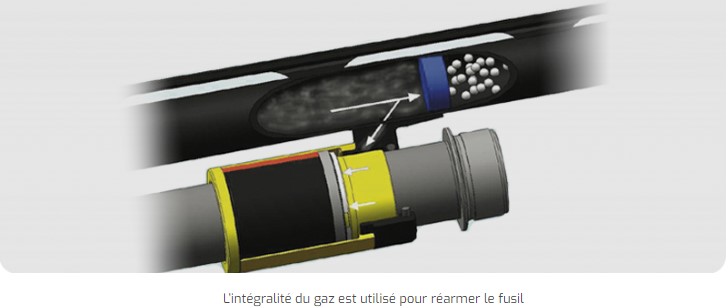

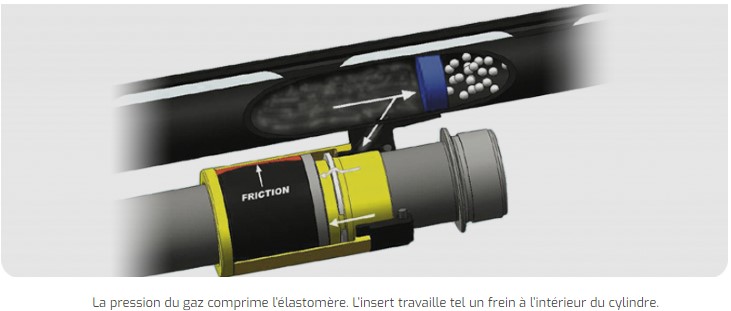

2. Pulse Piston

A piston with a flexible polymer insert to regulate the reset: it works like a progressive brake inside the gas cylinder. More valve and the possibility, more than ever, to fire all types of cartridges with an incredible reduction in recoil.

Perfect with all cartridges

With lightly loaded cartridges

With heavy duty cartridges

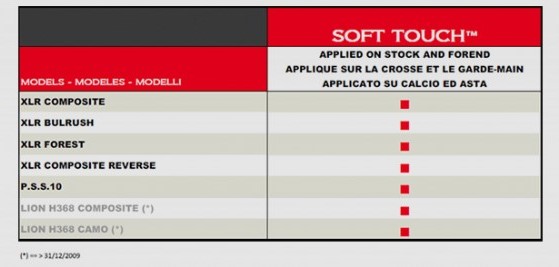

3.Soft touch

SOFT TOUCH is a specific coating applied to the stock and handguard to improve grip and handling, including in the rain or at very low temperatures. Treated in this way, a composite or CAMO finish stock takes on a rubbery feel. This Treatment also makes the composite very quiet and is a very resistant coating.

4. Triwood finish

The TRIWOOD™ finish introduced by FABARM in 2002 is a technical process to increase the aesthetic appearance of walnut and guarantee perfect protection against humidity.

TRIWOOD™ maintains the warm appearance of wood, each stick is unique.

The quality of the walnut and its grain are very important to obtain a perfect TRIWOOD™ stock. The secret is to arrive at the right sum of original and artificial veins.

TRIWOOD™ is not a film fixed to the wood, it is simply a deposit of ink on the wood.

TRIWOOD™ stocks are protected by a very resistant satin acrylic varnish.

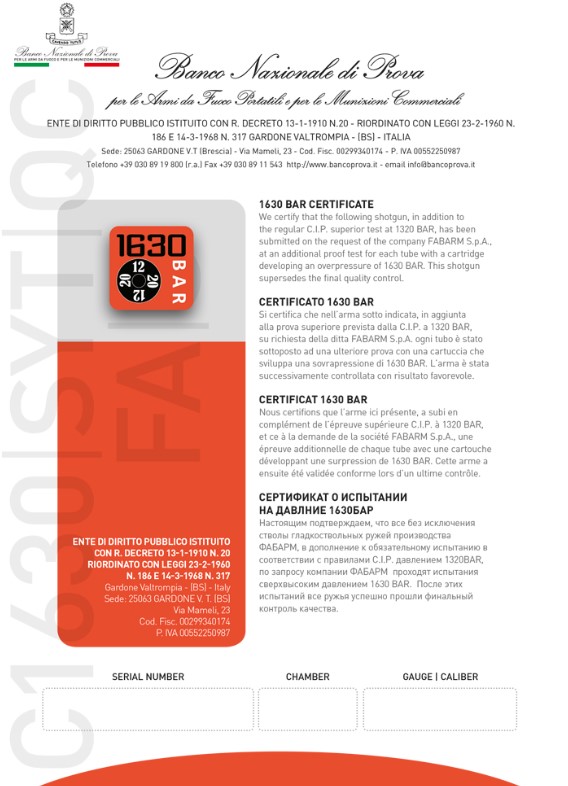

5. 1630 BAR Certification

FABARM is the only manufacturer to have concluded a test protocol at 1630 BAR with the CIP test bench in Gardone Val Trompia. Each FABARM rifle covered by this exclusive test (the legal CIP test provides for a pressure of only 1320 BAR) is delivered with a 1630 BAR test certificate. The safety of our customers is our top priority.